TEXTURED Fibre Cement Facade Panels.

CemCloak Tex

Nature-Inspired Elegance: Textured Fibre Cement Board Emulating Wood and Brick Aesthetics for Exquisite Facades.

Perfectly Textured. Natural. Fibre Cement Textured Facade Boards.

Description

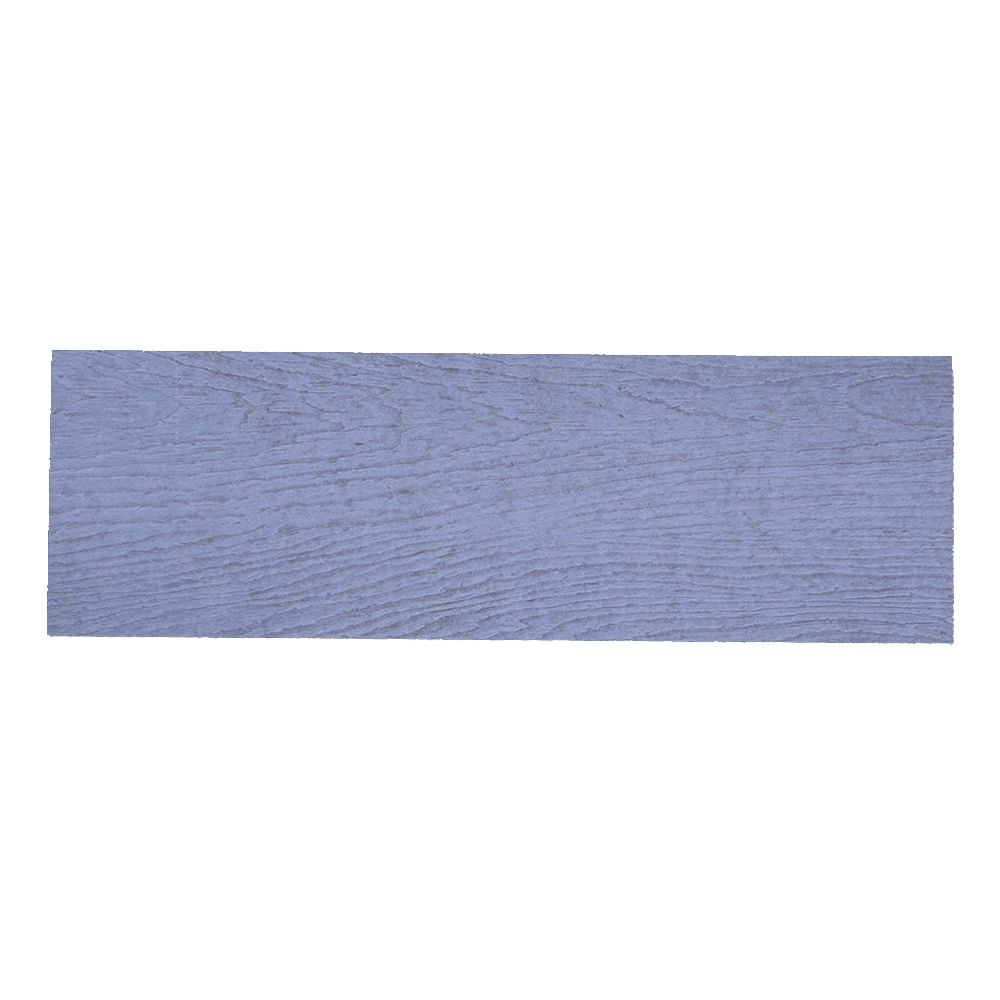

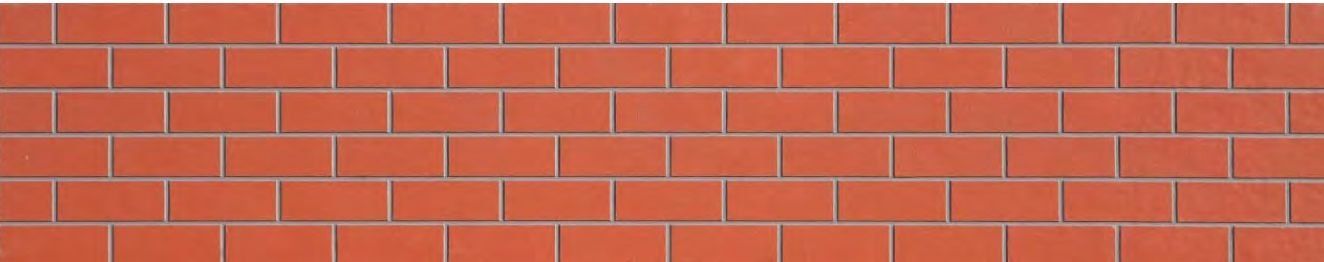

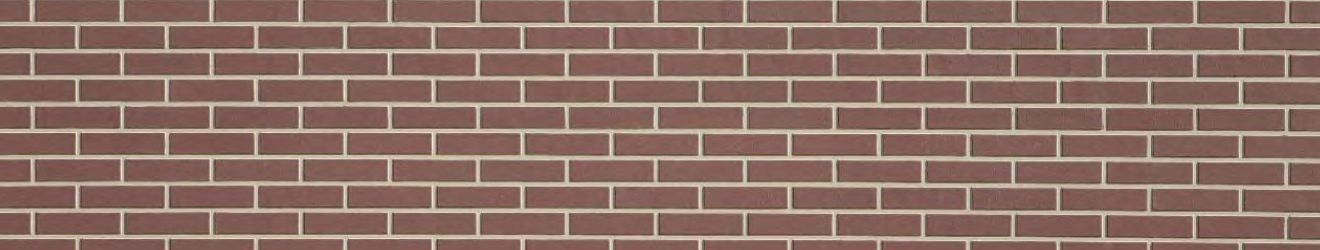

CemCloak Tex is a high performing textured decorative solution, specifically designed to provide visually stunning textures for facade cladding on both external and internal applications. The Tex is produced to show the warmth that wood adds to facades with its wood grain effect and the natural look that stone and brick radiate as light permeates their surface. Cellulose Fibre reinforced and autoclaved high density fibre cement board. It is Impermeable to water and is A1 fire rated, is UV stable and fully weatherproof even at freezing temperatures.

Ideal for any construction or renovation project, each high performance CEMBLOC® fibre cement façade panel range has been rigorously tested and achieves an A1 fire rating, alongside weather, impact and rot resistance. Featuring a 15mm thickness for additional impact resistance and heat preservation. With the colour of the boards not changing even after being directly targeted by UV/ high and low temperature for 6-12 years.

A beautiful effect may be created quite simply by alternating the direction of the lined texture from panel to panel across the span of a façade.

Key Features

Standard Sizes

Thicknesses: 15mm

Dimensions: 615mm x 2800mm, Plank natural texture available in 215mm x 2440mm

Fire Performance:

A1 Fire Class

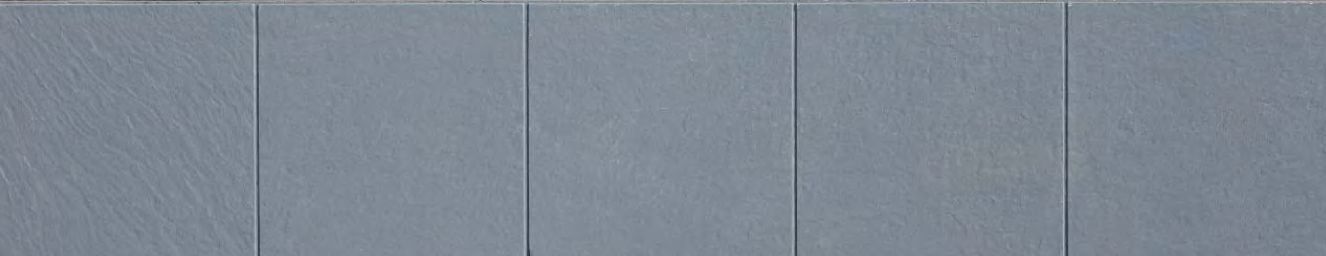

Styles:

CemCloak Tex Brick - Brick

CemCloak Tex Plank - Plank / Wood

Support for Your Project

Have a technical advisor get in touch to discuss your needs and work out a suitable, effective solution for you. Get a quote, our experts are here to help you find the best solution for your project. Call us today:

+44 (0) 208 050 5302

or send an email to

support@cembloc.com

Advantages Of Use.

- Protects sub-construction system.

- Dirt proof.

- Environment friendly.

- Does not contain any harmful substances to health.

- Asbestos free.

- A1 Fire Class

- Does not release toxic gas during the fire.

- Resistant to moisture and water.

- Resistant to the effects of sunlight.

- Resistant to seasonal changes.

- Easy assembly and modification procedures.

- Easy to cut.

- A finishing material, eliminates drying times of wet screed.

- Extends and protects the life of insulation material when used in heat and sound insulation systems.

- Extremely high dimensional stability (<0.19%) when compared to chipboard, gypsum and cement particle.

- Has feature of water repellent.

- It is odourless and does not release toxic gas.

- Resistant to impacts.

- Resistant to biological and chemical wastes.

- Easy to carry, light weight.

- Insect-proof, non-putrescible, no molding.

- Offers different solutions in all areas of building projects.

- Creates facades and surfaces compatible with fire regulations.

- Can be used with insulating material of any desired thickness.

- Can be used in fine details with smooth cutting surfaces.

- Very high impact resistance compared to gypsum based boards.

Available Brick Styles.

Areas Of Use.

- External facade

- Internal facade

Downloads