Hybrid Polymer Adhesive / Sealant

CemBond Max Strength 285Ml

CemBond is creation of combining both a sealant and adhesive through Hybrid polymer technologies

CemBond is creation of combining both a sealant and adhesive through Hybrid polymer technologies, the all in one product for the CemBacker®/ CemPlate® and Drybloc® TG4 ranges.

Combining the benefits of both polyurethane (mechanical strength) and silicones (elasticity).

Description

CEMBOND-MAX Strength Adhesive, the ultimate solution for all your bonding and sealing needs connection joints in across CEMBLOC® products! Combining the benefits of both polyurethane (mechanical strength) and silicones (elasticity). Which allows for timber expansion without cracking and watertightness in the build. This revolutionary, solvent-free hybrid polymer adhesive is based on the latest polymer technology, and offers excellent UV resistance and primerless adhesion to most substrates. When cured, it forms a tough, elastic sealant that can withstand harsh conditions and resist abrasion, oil and solvents.

Our professional team are here to help you with any questions.

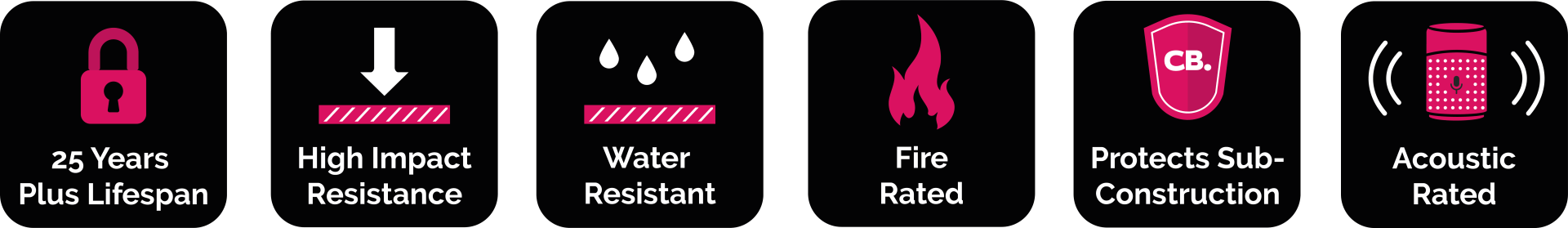

Key Features

Standard Sizes

285ml

Used With

CemBacker®/ DryBloc® TG4 and CemPlate® Ranges

Coverage

One 285ml cartridge is sufficient to seal approximately:

10 metres with a 6mm bead

17.2 metres with a 4.5mm bead

Drying Colour

White

Support for Your Project

Have a technical advisor get in touch to discuss your needs and work out a suitable, effective solution for you. Get a quote, our experts are here to help you find the best solution for your project. Call us today:

+44 (0) 208 050 5302

or send an email to

support@cembloc.com

Applications

Construction uses include perimeter sealing of the CemBacker boards along with the sealing of expansion and construction joints, it may be used on moist surfaces. This product is also suitable for many applications within the automotive, Roofing, marine and coachwork industries. Suitable for sealing and bonding connection joints in cement building boards, ducting, ventilation and air conditioning installations.

Application Instructions

Surfaces to which the CemBond is to adhere to. Ensure the area of application is clean and free from loose material, standing water or contaminants, which otherwise may impair the bond. Non-porous surfaces such as aluminium should be cleaned with a suitable product. CemBond may be necessary to prime some porous surfaces depending on cohesiveness and porosity of the substrate. For application where some movement will be exhibited i.e. construction joints, the minimum joint dimensions should be 6mm x 6mm with the maximum dimensions being 20mm wide by 12mm deep. Where deeper joints are found, depth can be reduced using a suitable backer rod. Areas of perimeter pointing where a fillet is to be applied, the minimum measurement across must be 10mm with a minimum depth of 6mm. If conditions are suitable for application, ensure joints are properly prepared and apply sealant firmly into the joint using an application gun. Ensure a good solid fill is achieved. Once applied, sealant can be tooled within 10 minutes to required finish. The cured sealant can be painted if required but is not necessary. Painting sealant in a movement joint is not recommended as the movement of the sealant may be greater than the flexibility of the paint, leading to cracking or crazing of the paint film.

Limitations

CemBond should not be used to seal aquariums. Submerged joints need special attention to surface preparation and application and should be checked for integrity at regular intervals. Always check to determine suitability of the sealant on any surface that may give cause for concern.

Storage

Store in dry conditions between 5°C and 25°C. Shelf life is 16 months when stored in unopened cartridges under cool, dry conditions and will perform in excess of 20 years in service if applied correctly.

Health And Safety

- Consult Health and Safety Data Sheet. (MSDS)

- Avoid contact of uncured sealant with the skin. If uncured sealant comes into contact with eyes, flush out immediately with clean water for at least 5 minutes and seek medical advice.

- Use in a well-ventilated area.

- Care should be taken during use and storage.

- Do not use with food or drink around and ensure hands have been adequately washed prior to eating or drinking.

- Keep away from children and animals.

Further Information

This data is offered in good faith and are typical values, not as a product specification. No warranty, either expressed or implied, is hereby made. The recommended industrial hygiene and safe handling procedures are believed to be generally applicable, each user should review these recommendations in the specific context of the intended use and determine whether they are appropriate.

Downloads