MULTI SURFACE PRIMER

CemBond SBR 1L / 5L (Trade)

Applications include waterproofing basement structures, underlying levelling screeds, wear resistant flooring or in concrete repairs.

CEMBOND SBR is a styrene-butadiene emulsion which offers excellent adhesion to fibre cement, concrete, brickwork masonry, renders and steel.

Excellent adhesion to concrete, brickwork, masonry, renders, and steel.

Description

CEMBOND SBR is a styrene-butadiene emulsion which offers excellent adhesion to fibre cement, concrete, brickwork masonry, renders and steel. It also imparts excellent waterproof and weather resistant properties. Applications include waterproofing basement structures, underlying levelling screeds, wear resistant flooring or in concrete repairs. It can also be used as an admixture to improve flexibility, tensile strength and reduced shrinkage.

Porous surfaces such as fibre cement, concrete, brick, etc, should be thoroughly dampened with clean water just prior to priming, ensuring that no free standing water is remaining. Timber surfaces should be sealed with CEMBOND SBR. The Priming Slurry should be applied by brush or roller, scrubbing well on to the surface to ensure complete coverage of substrate.

CEMBOND SBR should be protected from freezing and excessive heat. Containers when not in use should be kept sealed. If stored in accordance to the above recommendations, CEMBOND SBR will have a shelf life in excess of 12 months.

Our professional team are here to help you with any questions.

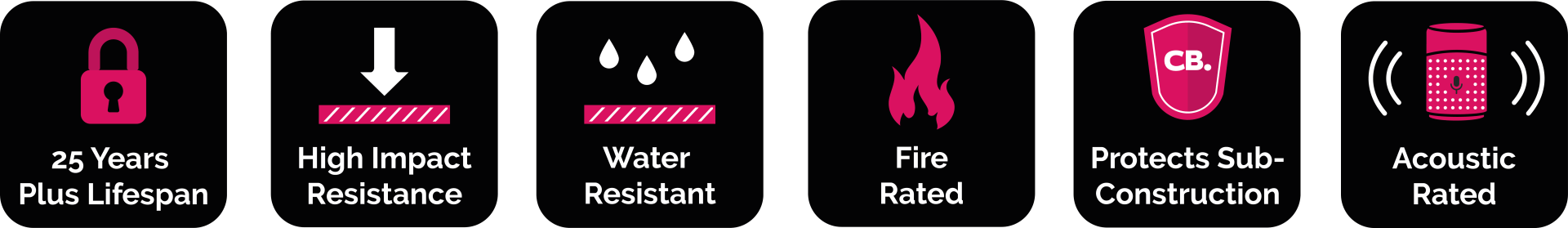

Key Features

Standard Sizes

1 Litre

5 Litre

Used With

CemBacker/ DryBloc TG4 and CemPlate Ranges

Coverage

One 1 Litre bottle is sufficient to seal approximately:

7m2 0 dilution

14m2 1:1 dilution

Support for Your Project

Have a technical advisor get in touch to discuss your needs and work out a suitable, effective solution for you. Get a quote, our experts are here to help you find the best solution for your project. Call us today:

+44 (0) 208 050 5302

or send an email to

support@cembloc.com

Advantages

• Water resistant screeds and renders.

• Waterproofing basement structures.

• Underlayment levelling screeds.

• Resurfacing mortars with feather edging properties.

• Concrete repairs.

• Bonding mortars to existing concrete or steel.

• Weather resistant adhesives for brick slips, ceramic tiles, kerbs, coping stones and blocks.

• Grouts for sealing cracks in brickwork and masonry.

• Mortars for spraying by the grunting process.

• Bonding new concrete to old.

• Excellent adhesion to concrete, brickwork, masonry, renders, and steel.

• Waterproof and weather resistant properties.

• Improved tensile and flexural strengths.

• Greater flexibility.

• Improved resistance to abrasion.

• Wear resistant flooring.

• Reduction in curing shrinkage.

• Reduced preparation on walls and floors prior to application of screeds and renders.

Applications

All surfaces must be sound, clean, and free from dust, loose materials, oils, grease and other deposits. Concrete surfaces should be free from laitance and for best results scarification or acid etching is recommended. Cracks in concrete should be cut out to a minimum depth of 25 mm and of sufficient width to enable complete filling with mortar during the resurfacing operation. Steel surfaces such as exposed reinforcing steel should be free from rust and scale; either grit blasting or wire brushing may achieve this.

Application Instructions

Porous surfaces such as fibre cement, concrete, brick, etc, should be thoroughly dampened with clean water just prior to priming, ensuring that no free standing water is remaining. Timber surfaces should be sealed with CEMBOND SBR. The Priming Slurry should be applied by brush or roller, scrubbing well on to the surface to ensure complete coverage of substrate.

Storage

CEMBOND SBR should be protected from freezing and excessive heat. Containers when not in use should be kept sealed. If stored in accordance to the above recommendations, CEMBOND SBR will have a shelf life in excess of 12 months.

Health And Safety

Prolonged physical contact should be avoided and personal and environmental hygiene encouraged in common with the use of all chemical products. Where contact with skin occurs, the material should be removed with soap and water. If splashes affect eyes, they should be bathed immediately with clean water and if discomfort persists medical attention should be sought.

See Safety Data Sheet for further information.

Downloads