High-Performance Soundproof Underlay

DeciBloc® NRS03 & NRS05

High-Performance Soundproof Flooring Solution for Residential & Commercial Buildings

DeciBloc® NRS series has been engineered from Recycled Rubber to Reduce Impact Noise, Improve Acoustic Comfort, and Deliver Long-Lasting Flooring Performance

Pre-Routed Fibre Cement Boards Designed for Effortless 12mm UFH Pipe Installation and Superior Thermal Performance

Description

DeciBloc® NRS03 and NRS05 (Noise Reduction System) 3mm / 22dbΔLw and 5mm / 23dBΔLw Acoustic Underlay is a sustainable, high-performance solution designed to significantly reduce the transmission of impact sound and footfall noise across a wide range of flooring systems. Manufactured from environmentally friendly recycled tyre rubber and formed through high-temperature hot pressing, this underlay combines durability, acoustic performance, and eco-conscious design.

Tested by independent accredited laboratories, the DeciBloc® Acoustic Underlay has been proven to deliver superior impact sound reduction, making it suitable for both residential and commercial projects where acoustic comfort is a priority. It can be installed directly under screed or gypsum concrete and is compatible with concrete, steel, and timber constructions.

The material is mould, bacteria, fungi, and water-resistant, ensuring long-lasting performance even in demanding environments. Its robust design will not fail under high point loads, while the easy-to-roll format ensures fast installation on site. Backed by an IIC acoustic performance report, DeciBloc® Acoustic Underlay is a trusted choice for architects, contractors, and developers looking to meet acoustic regulations and improve building comfort.

Our professional team are here to help you with any questions.

Key Features

Standard Sizes

Dimensions:

1,000mm*20,000mm*3mm

1,000mm*10,000mm*5mm

Product Type

Roll

Performance

3mm - 22dbΔLw

5mm - 23dBΔLw

Support for Your Project

Have a technical advisor get in touch to discuss your needs and work out a suitable, effective solution for you. Get a quote, our experts are here to help you find the best solution for your project. Call us today:

+44 (0) 208 050 5302

or send an email to

support@cembloc.com

Advantages Of Use.

- Superior acoustic performance – independently tested to significantly reduce impact and footfall sound

- Sustainable material – manufactured from environmentally friendly recycled tyre rubber

- Moisture and microbial resistant – protects against mould, bacteria, fungi, and water ingress

- Strong and durable – will not fail under high point loads, ensuring long-lasting reliability

- Easy to install – supplied in convenient rolls or sheets that lay flat and roll out quickly

- Versatile compatibility – suitable for use under screed, gypsum concrete, and a variety of floor finishes

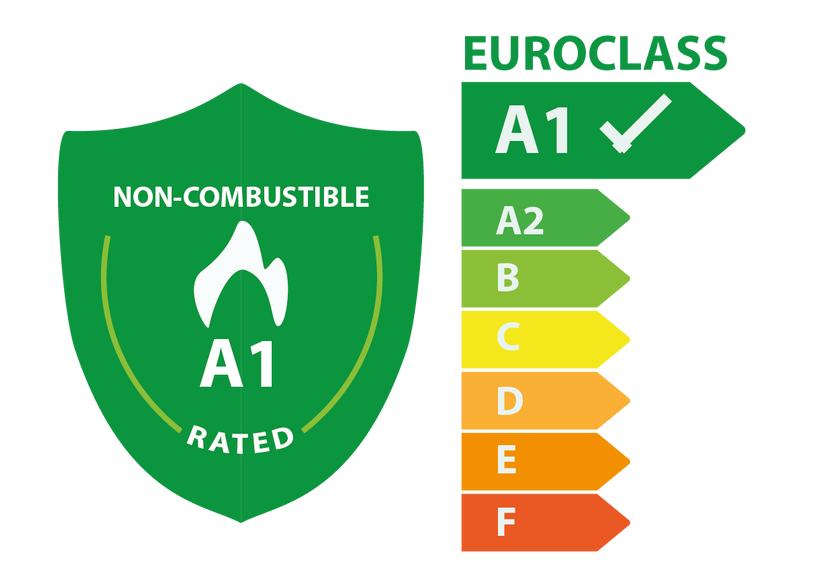

- Fire and safety tested – compliant with building regulations and acoustic standards

- Certified for sound insulation performance in residential and commercial buildings

Areas Of Use.

- Residential flooring systems – ideal for homes, apartments, and high-rise residential blocks

- Commercial buildings – offices, hotels, restaurants, and retail spaces requiring improved acoustic comfort

- Public buildings and institutions – schools, hospitals, care homes, and community centres

- Under screed systems – works directly beneath screed or gypsum concrete to enhance sound insulation

- Concrete, steel, and timber constructions – versatile use across multiple building structures

- Renovations and refurbishments – effective upgrade for existing flooring to meet modern acoustic requirements

- Multi-storey developments – reduces transmission of noise between floors, meeting compliance standards

Downloads