UFH ROUTED FLOOR BOARDS

DryBloc® HeatFlow 18

18mm CNC Routed Board for Wet Underfloor Heating – Fast, Durable, and Precise Pipe Installation

DryBloc® HeatFlow CNC Routed Board is a high-performance fibre cement board designed for effortless wet underfloor heating (UFH) installation, ideal for applications including 12mm pipework systems, concrete and timber floors, wet rooms, bathroom renovations, and tiled flooring projects.

Pre-Routed Fibre Cement Boards Designed for Effortless 12mm UFH Pipe Installation and Superior Thermal Performance

Description

The CEMBLOC® DryBloc® HeatFlow is a CNC Routed Board is a high-performance fibre cement solution engineered specifically for wet underfloor heating (UFH) systems. Each board features precisely CNC-routed grooves to securely house 12mm UFH pipework, ensuring consistent alignment, faster installation, and optimal heat distribution. Designed to simplify both residential and commercial UFH projects, these boards significantly reduce installation time compared to traditional pipe-fixing methods while maintaining a professional finish.

Manufactured from high-density fibre cement, the DryBloc® HeatFlow UFH board is exceptionally durable, moisture-resistant, and thermally stable, making it suitable for wet rooms, bathrooms, kitchens, utility areas, and any space requiring reliable underfloor heating. Its 18mm thickness and 1200x600mm dimensions offer the perfect balance between rigidity and ease of handling, while pre-routed grooves prevent pipe movement and ensure long-term performance of the heating system.

This board is compatible with concrete screeds, timber joist floors, and hybrid flooring systems, making it versatile for new builds, renovations, and refurbishments. Beyond underfloor heating, it also supports tiled, wooden, or laminate flooring, providing a stable and moisture-resistant base. Whether used in domestic properties, commercial offices, hotels, gyms, or wellness centres, DryBloc® HeatFlow Wet UFH CNC Routed Boards deliver efficient heat transfer, robust construction, and ease of installation, making them the ideal solution for modern UFH flooring systems.

Priming is required after laying and pipe installation to protect pipes and optimise screed adhesion

Our professional team are here to help you with any questions.

Key Features

Standard Sizes

Thicknesses: 18mm

Dimensions: 1200mm x 600mm

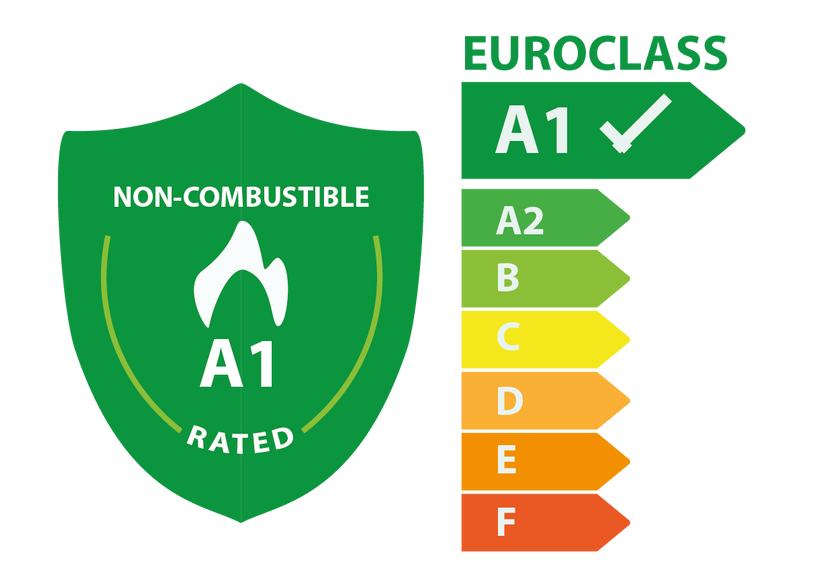

Fire Performance

A1 Fire Class

Side Profile

Flat edge

Span

N/A - Overlay board only.

Support for Your Project

Have a technical advisor get in touch to discuss your needs and work out a suitable, effective solution for you. Get a quote, our experts are here to help you find the best solution for your project. Call us today:

+44 (0) 208 050 5302

or send an email to

support@cembloc.com

Advantages Of Use.

- CNC-routed grooves for precise 12mm wet UFH pipe placement

- High-density fibre cement for superior durability and strength

- 18mm thickness, compatible with standard UFH screed applications

- 1200x600mm size, lightweight and easy to handle on-site

- Moisture-resistant, suitable for wet areas and high-humidity environments

- Fire-resistant, providing additional safety in residential and commercial spaces

- Compatible with concrete screeds, timber joist floors, and hybrid systems

- Reduces installation time compared to traditional pipe-fixing methods

- Prevents pipe movement and ensures even heat distribution

- Long-lasting performance in both new-build and renovation projects

Areas Of Use.

- Residential projects: bathrooms, kitchens, utility rooms, conservatories

- Commercial spaces: offices, hotels, gyms, wellness centers

- New-build flooring systems where UFH is required

- Renovations and refurbishments requiring quick UFH integration

- Concrete screed floors

- Timber joist floors

- Wet rooms and areas with high moisture levels

- Underfloor heating in combination with tiled or wooden floors

Downloads