The purpose of this article is to educate and provide evidence-based resources to the UK market on the comparison of MgO and Fibre Cement. We will compare key factors such as price, fire safety, water resistance, and focus on durability, a crucial factor often overlooked. We will examine construction industry practices to highlight potential issues with MgO, enabling you to make an informed decision.

Risks of MG0 Boards?

To start this article is best to dive into the deep end. As of April 2020, NHBC (National House-Building Council) announced "NHBC will not accept MgO building boards on buildings where the foundations are begun on or after 30 April 2020 under its insurance warranty" and "Where MgO building boards have already been, and are currently being, installed on buildings, you should use an alternative product if it is practical to do so."

- Reference: https://www.nhbc.co.uk/builders/products-and-services/techzone/technical-updates

Alongside NHBC, the LABC announced "LABC Warranty no longer accept the use of all types of Magnesium Oxide board (MgO) on any of our structural warranty schemes." 15 days earlier.

- Reference: https://www.labcwarranty.co.uk/technical-blog/updated-guidance-for-magnesium-oxide-boards-mgo

Leading render manufacturers have prohibited the use of MgO boards with their renders, as per their "red list, following the withdrawal of LABC, NHBC and their own findings.

Why The Discontinuation of MG0 Boards In Construction?

The discontinuation of MgO use was prompted by a 2017 study from the Technical University of Denmark that revealed moisture damage issues with magnesium oxide boards."and they begin to leak salty water, which is highly corrosive, and leads to moisture and mould problems in wooden members of the structures." leading onto a repair bill "which has had detrimental consequences, such as an expected cost of repair of around 2 billion DKK." when converting into todays value in GBP the cost is in excess of £300million (three hundred million pounds).

- Reference: https://www.sciencedirect.com/science/article/pii/S1876610217349378

Concerns were raised down under, when both School of Science and Engineering and College of Engineering, Australia had "raise questions about the appropriateness of magnesium oxide boards" following their study of hygrothermal performance of magnesium oxide (MgO) boards.

- Reference: https://www.sciencedirect.com/science/article/abs/pii/S0950061821021875

Followed by a released finding that shows "Magnesium oxide (MgO) wallboards have been linked to damages reported globally and within Australia. These damages include dampness, cracking, and accelerated corrosion of contacting metal fixtures."

- Reference: LINK

Effects of MG0 board in Steel Structures?

Credit to: School of Science and Engineering, University of the Sunshine Coast, Maroochydore, Qld 4556, Australia

The image above shows Zinc covering of the steel profile is corroded as a result of direct contact with salty leaked water from the adjacent MgO-board

The effect of using MgO boards caused the "Salt from MgO-boards is highly corrosive on metal fasteners and profiles. Zink flashings of 0.8 mm corrode in 1- 2 years. Electro galvanized steel profiles, nails and screws will corrode through to the steel in 1-2 years. Aluminum alloys have different resistance against corrosion and the best alloys have been seen undamaged for 2-3 years. Stainless steel of A2 and A4 can be used without problems. When MgO boards have been sitting on a wooden structure, MgCl2 salt will have been absorbed by the wood, which is then corrosive to metallic fasteners other that stainless steel"

Reference: https://www.sciencedirect.com/science/article/pii/S1876610217349378

Alternatives to MgO Boards?

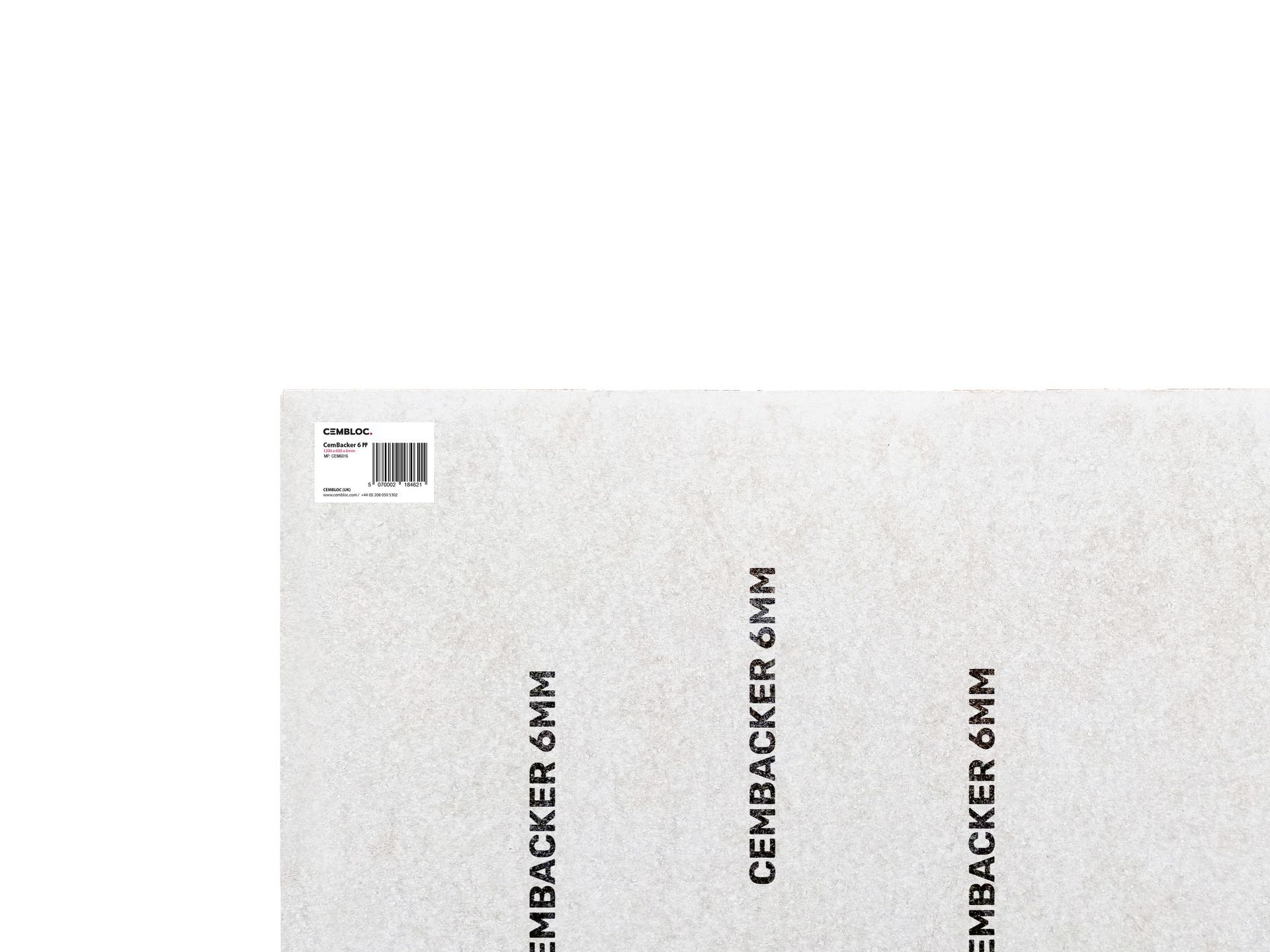

Fibre Cement is a preferred alternative to MgO, recommended by leading render manufacturers and the LABC. It is a versatile solution used as a sheathing, render carrier, and tile backer board. Fibre Cement is durable, fire-resistant, termite-resistant, moisture-resistant, and rot-resistant, making it low-maintenance and long-lasting. This makes it suitable for use in areas prone to natural disasters and environmental hazards.

The information in this blog post is based on third-party references and sources we believe to be reliable. However, we make no guarantees regarding the accuracy, completeness, or reliability of the content. The summary provided is for general informational purposes only and should not be considered as professional advice. Readers are encouraged to verify any information before relying on it for their own purposes.